The Future of Road Construction: Innovations Driving Safer and Smarter Infrastructure

Introduction

Road infrastructure remains a backbone of economic development, urbanisation, and mobility worldwide. Yet, the industry faces growing demands: heavier traffic loads, stricter environmental regulation, climate-related stresses, and rising expectations around safety and durability. For contractors, governments, and technology providers, the imperative is clear: build roads that are not just cheaper and faster, but smarter, safer and more sustainable.

In this article we explore how innovations in materials, machinery, data and process are transforming how roads are designed, built and maintained. We highlight cutting-edge technologies, explain why they matter, and link them to what project and budget managers should be watching. For a construction project management system like PrecisionSpan, this vantage point positions your brand as a knowledgeable partner in the road-infrastructure domain.

Where the Road Construction Industry Stands Today

Before diving into the innovations, it’s useful to sketch the key pressures that the road-building sector currently faces:

- Demand and scale: Governments around the world continue to invest large sums into highways, expressways, rural roads and infrastructure networks. The sheer scale means more projects, larger budgets and higher complexity.

- Cost and time overruns: Many road projects still suffer from delays, budget creep, material wastage and logistical bottlenecks. The traditional processes are under strain.

- Safety and durability: Roads are expected to last longer and handle greater loads, with minimal disruption for maintenance. Additionally, increasing traffic volumes and higher speeds raise safety stakes.

- Environmental and sustainability pressures: From carbon footprint constraints to using recycled materials, the road-construction sector is being asked to do more with less impact.

- Technology gap: While other sectors have rapidly embraced digitalisation, road construction has often lagged behind but that gap is now closing quickly.

Given this backdrop, the innovations we discuss below aren’t just “nice to have” they are becoming essential.

Innovations in Materials: Smarter, More Durable Road Surfaces

One of the foundational levers for safer and smarter roads lies in the materials themselves. Recent developments include:

1. Recycled and Alternative Materials

The use of recycled plastic, industrial by-products and novel geocells is gaining traction. For example, roads constructed using recycled plastic waste show improved durability and reduced potholing. In particular, plastic-bitumen blends have been trialled in India with thousands of kilometres laid.

These materials address multiple goals: reducing waste, cutting carbon emissions, extending pavement life, and lowering maintenance costs.

2. Self-Healing and Smart Asphalt

Imagine a road surface that heals its own cracks autonomously. Researchers are developing “self-healing” bitumen or asphalt mixes that release healing agents when minor cracks form, thus preventing the progression of damage.

Similarly, “smart asphalt” embedded with sensors or energy-harvesting components (piezoelectric materials) is becoming a reality. These pavements monitor stresses, traffic loading and environmental conditions.

3. Dynamic and High-Performance Road Markings & Surfaces

Beyond the pavement itself, road markings and surfaces are undergoing innovation. “Glow-in-the-dark” markings, thermochromic paints that change colour in sub-zero conditions, noise-reducing asphalt mixes these are no longer futuristic.

For example, dynamic road markings improve visibility and safety at night or in adverse conditions. This contributes directly to the “safer” part of smart infrastructure.

4. Integrated Renewable Energy and Sensor Infrastructure

Some roads are being designed not just as transport corridors but as energy infrastructure. Roads embedding solar panels, or pavements designed to harvest vibration or thermal energy, are in experimentation.

This convergence of transport and energy infrastructure may seem ambitious, but for forward-thinking clients it offers long-term value in terms of systems integration and lifecycle cost savings.

Innovations in Equipment, Automation and Digital Process

While materials set the foundation, the way roads are built and managed is also evolving rapidly thanks to machinery and digitalisation.

1. Autonomous and Semi-Autonomous Construction Machinery

Heavy equipment (pavers, rollers, graders, excavators) is increasingly equipped with GPS, LiDAR, AI-driven controls and remote operation capabilities.

These machines offer improved precision (e.g., uniform paving thickness, correct gradient), better productivity (24/7 operations in some cases) and enhanced safety (less human exposure to dangerous work zones).

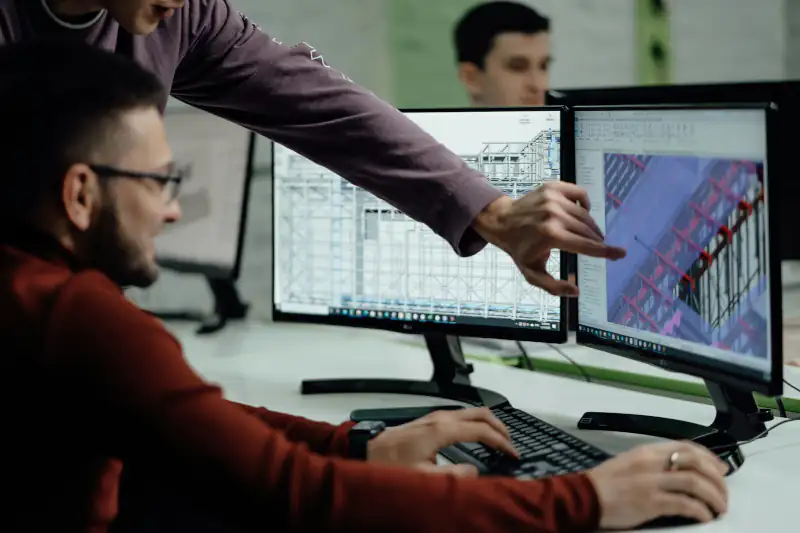

2. Drones, LiDAR, 3D Scanning for Surveying and Monitoring

Project sites are leveraging drone surveys and mobile LiDAR scanners to quickly gather high-resolution terrain and site data.

This enables faster site set-up, more accurate earthworks estimation, real-time progress tracking and early detection of deviations from design. For road construction, where accuracy of gradient, drainage, compaction and alignment matters, this is a game-changer.

3. IoT, Big Data and Predictive Maintenance Platforms

Road networks are being instrumented with sensors to monitor surface condition, traffic loads, wear and tear, weather impacts and structural health. When paired with analytics, AI and machine learning, these platforms can predict where maintenance will be needed, what interventions will be most cost-effective, and thus reduce unplanned downtime.

In practical terms this means longer-life pavements, fewer disruptions, and lower lifecycle costs which is highly relevant to asset owners and contractors alike.

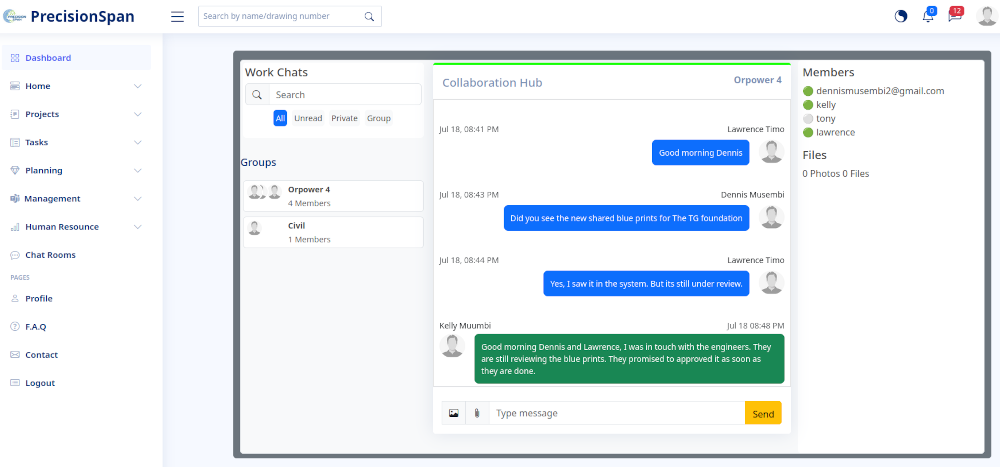

4. Digital Project Management and Workflow Integration

True “smarter infrastructure” isn’t just about physical roads, but about the process: integrated planning, scheduling, resource allocation, real-time tracking, and feedback loops. Software systems that tie together site data, equipment status, material usage, labour and budget info create powerful visibility and control.

For example, a project-management tool that feeds in sensor data from smart materials, equipment telemetry from automated machinery, and site progress via drones gives managers a single source of truth. This helps reduce delays, change-order risks and cost overruns.

Enhancing Safety and Sustainability Through Smart Designs

Innovation isn't just about speed and cost two critical dimensions for road infrastructure are safety and sustainability.

Safety: From Design to Maintenance

- Smart road markings and dynamic signage increase visibility and driver awareness.

- Automated monitoring systems detect defects in signs, surface damage or hazards and trigger maintenance.

- Autonomous vehicles and robotics reduce the need for human workers in high-risk zones (e.g., paving, excavation) increasing worker safety.

- Real-time traffic management enabled by embedded sensors and connectivity can respond to adverse conditions, redirect traffic or activate warnings decreasing accident risk.

Sustainability: Lifecycle Thinking & Circular Economy

- Using recycled materials (plastic, rubber, industrial waste) in pavements reduces raw-material consumption and landfill burden.

- Self-healing materials and data-driven maintenance extend pavement life, thereby reducing frequency of disruptive repairs and resource use.

- Smart energy-harvesting roads (solar, piezoelectric) turn a cost centre (roads) into infrastructure that recoups energy, offsetting environmental impact.

- Digital planning and optimisation reduce waste, idle equipment, material over-ordering and site inefficiencies.

Implications for Road Construction Project Management

What do all these innovations mean for managers, contractors and clients? Here are key implications and practical considerations:

1. Early-Stage Planning Must Include Technology Strategy

Incorporating smart materials, sensors or automated equipment into a road project means your planning phase must account for tech readiness, supply-chain access, maintenance regimes, training and data-integration. A digital project-management system becomes as important as asphalt mix design.

2. Data Becomes a Strategic Asset

With smart sensors, scanning devices and IoT systems in place, project performance is no longer just about “tons of asphalt laid” or “metres of road opened”. It’s about condition forecasts, predictive maintenance schedules, asset-lifecycle tracking. Make sure your workflow supports this.

3. Budgeting and Risk Management Must Adapt

Adopting new materials or automated machines often bring higher upfront costs. But their value lies in extended lifespan, lower maintenance and fewer disruptions. Budget models must move from “first cost” to “whole-life cost”. Similarly, risks such as technology integration delays, staff training gaps or data-security concerns must be recognised and managed.

4. Collaboration Between Stakeholders Becomes Crucial

Smart road projects involve multidisciplinary teams civil engineers, ICT specialists, data analysts, equipment manufacturers, environmental experts. Project-management tools must support cross-team workflows, communication and change-management.

5. Maintenance and Asset Management Are Now Part of Construction Strategy

Because roads are becoming instrumented and monitored, the “maintenance phase” starts before the road opens. For example, sensors may detect early cracking or load stresses, triggering actions while the road is still under warranty or sooner than traditional cycles. Hence teams must integrate construction, commissioning and asset-management workflows seamlessly.

Challenges and Barriers to Adoption

Of course, while the future is exciting, it’s not without challenges. Below are some key barriers and how they might be overcome:

Higher Upfront Costs and Unfamiliar ROI Models

New materials and automation often come with higher initial investment. Stakeholders may question ROI when traditional methods are well-understood. Overcoming this requires building lifecycle cost models, showcasing case studies, and securing stakeholder buy-in.

Skills and Training Gaps

Operating sophisticated equipment, managing sensor networks or interpreting data analytics requires new skill sets. Training programmes and change-management become essential.

Integration and Interoperability Issues

Legacy equipment, manual workflows and siloed systems may not easily integrate with new digital tools. Standardisation, open-data platforms and modular design help.

Data Security and Privacy

With more connectivity comes more risk: cyber-security, data governance, reliable connectivity (especially in remote or rural road networks) must be addressed.

Regulatory and Standards Uncertainty

Road construction is heavily regulated. New materials, smart systems or energy-harvesting pavements may face unclear regulatory pathways or lack standard certifications. Active engagement with regulators is important.

Infrastructure Readiness and Market Maturity

In many regions, especially in developing markets, the ecosystem (suppliers, service providers, skilled labour) may not yet be mature for widespread adoption of advanced technologies. Pilot projects and phased roll-out are advisable.

Spotlight on Africa and Emerging Markets

For a company like PrecisionSpan operating in or servicing markets in Africa (or other emerging regions), there are particularly strong opportunities and considerations.

- Many African countries are investing heavily in road infrastructure to enhance connectivity, support trade corridors and stimulate growth. Smart-road technologies offer a way to leapfrog legacy systems.

- Materials innovation (e.g., recycled plastics, local waste streams) are especially relevant in regions where cost-control is critical and sustainability concerns are rising.

- Digital project-management tools help address common problems of delays, budget overruns and resource inefficiencies that are often more acute in emerging markets.

- However, challenges around connectivity, local skills, procurement ecosystems and regulatory maturity may be more pronounced. A hybrid approach (traditional + incremental innovation) often works best.

The Role of Construction Project Management Systems

As roads become smarter, so must the systems managing them. Here’s how a platform like PrecisionSpan can play a strategic role:

- Integrated Task & Dependency Management: Road construction involves many interdependent tasks (earthworks → base layers → surface, drainage, lighting, sensors). A system that tracks dependencies ensures nothing is missed.

- Real-Time Data Integration: If you have sensors in pavements or equipment telemetry, feeding this into your management system enables live dashboards, alerts and predictive maintenance triggers.

- Budgeting & Forecasting with Technology Variables: The tool must allow modelling of new-material costs, maintenance savings, lifecycle value, and help justify innovation investment.

- HR & Resource Management: As skills shift (smart equipment, data analysts, sensor technicians), managing resource allocation, training status and team deployment becomes essential.

- Risk Management: New technologies bring new risks integration failures, data issues, unproven materials. Your system must include risk modules, contingency plans and audit trails.

- Reporting & Stakeholder Communication: With smart road projects, stakeholders will expect dashboards showing not just progress but performance metrics (e.g., sensor health, pavement condition, traffic flow). A good system supports this transparency.

Looking Ahead: What to Watch in the Next 5–10 Years

What does the horizon look like for road construction innovations? Here are key trends to monitor:

- Widespread rollout of self-healing pavements:- as the technology matures, more roads will incorporate materials that autonomously repair minor damage, reducing maintenance frequency and cost.

- Energy-generating roads:- solar roads, piezoelectric pavements, kinetic-energy capture systems will become more viable, particularly in high-traffic or premium-location corridors.

- Fully autonomous road-construction sites:- from surveying drones, autonomous machines, automated materials delivery to digital twins controlling site operations, labour-intensive tasks will continue to drop.

- Connected vehicle and infrastructure synergy:- roads embedded with sensors, communication systems, vehicle-to-infrastructure (V2I) connectivity will enable smarter traffic management, predictive maintenance and enhanced user experience.

- Lifecycle and circular-economy models:- procurement will move from build-and-forget to build-monitor-maintain-replace cycles, emphasising sustainability, modular construction and materials reuse.

- Data-driven asset management at scale:- governments and agencies will increasingly rely on big-data platforms, AI-powered predictive maintenance and digital twins of road networks to optimise performance and budget allocation.

- Customised materials for local conditions:- In emerging markets, materials tailored to local waste streams (plastic, rubber, industrial by-products) will provide cost-effective and sustainable solutions.

Conclusion

The future of road construction is here: smarter materials, automated machinery, digital dataflows, and integrated systems are redefining what a road can be. For contractors, governments and project managers, the objective is no longer just building a pavement it’s constructing a connected, resilient, efficient infrastructure asset that delivers value over decades.

For a project management and construction-workflow platform such as PrecisionSpan, this is a golden opportunity. By aligning with these innovations supporting smart-road workflows, integrating data from sensors and equipment, tracking lifecycle budgets, and enabling better decision-making you position yourself not just as a software provider, but as a strategic enabler of the next generation of infrastructure.

If you’re ready to lead your clients into this smarter infrastructure era, the time to act is now. Build for safety, build for intelligence, build for longevity.

At PrecisionSpan, we understand how modern road infrastructure demands more than in-house spreadsheets and disconnected tools. Our platform integrates project scheduling, budgeting, workforce management and real-time data giving you full visibility and control over the most complex construction projects. Reach out today for a demo, and let’s build smarter roads together.

0 Comments